Port Tampa Bay Petroleum Improvements

Port Tampa Bay Petroleum Improvements

Tampa

Port Tampa Bay is the energy gateway for all of west central Florida, serving almost nine million people. Critical to consumers and the economic vitality of the region, all of the automobile gasoline and aviation jet fuel for the region’s airports (including Tampa and Orlando) moves through the Port. Modernization and expansion of the Port’s primary petroleum terminal was central to enable the Port to continue to underpin the region’s economic growth, viability and job creation.

The petroleum complex improvements, with a cost of $54 million, is comprised of three berths and manifolds, pipelines and related facilities to handle a diverse range of critical petroleum and liquid bulk products into Florida. This was a multi-phased project that consolidates facilities shared by multiple users, increases berthing space for ships, allowing for more and larger ships to dock and off load product. The facility is designed to handle more than 70 million barrels of fuel annually.

Design and construction of this project encompassed many separate elements with associated geotechnical engineering challenges.

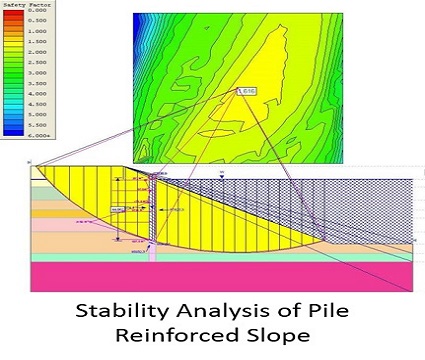

• Unstable slopes for Berth 222 were stabilized using vertical Displacement Cast In Place Concrete Piles (DCIP) as “reinforcement”.

• The bulkhead for Berth 227 was created into the bay without using costly dewatering by simply pushing the fill from the shore, densifying it with a vibrating steel beam and verifying compaction with Cone Penetrometer soundings.

• Pipe racks were supported on single, shallow DCIP’s instead of traditional shallow footings, thus reducing the surface footprint and saving time and cost.

• The mooring dolphin foundations, which required significant lateral and uplift resistance, were innovatively constructed by driving 72” diam. steel casing to rock and drilling through the casing into the hard rock to create a combined steel shaft/rock socket foundation.

• The project entailed services during design and construction and required timely response to changes in foundation construction methods and, in one case, an accidental oil spill which was evaluated and remediated quickly so as not to impact the schedule.

The project was completed according to the schedule and within the project budget.